6071 - HVAC/R Program - 600 Hours

This Program Consists of all four sections below:

This program is designed for those with little or no experience in the Heating, Ventilation, Air Conditioning and Refrigeration industry with a goal to begin a career in the HVAC/R industry. The student will progressively complete each course within the program to acquire the entry level skills in each unit of the course. Students who complete all courses and make successful academic progress and maintain attendance will graduate and receive a Certificate of Completion. Upon successful completion of the program, graduates will have the necessary skills to start a career in the HVAC/R industry. This program also provides the EPA Certification 608 Exam & OSHA 30.

All Trades Program – 150 Hours

Provides a basic overview of construction trade, hand and power tool operations, 40 Hour Site Safety Training, (includes 30 Hour OSHA) and professional development.

● Intro to Construction Math

● Basic Communication Skills

● Intro to Hand Tools

● Customer Relations

● Intro to Power Tools

● Intro to Material Handling

● Intro to Basic Rigging

● Basic Employability Skills

* 2 Hour Drug & Alcohol Awareness

* 8 Hour Fall Prevention

* 30 Hour OSHA Training

* Site Safety Training Card Fulfills NYC DOB LOCAL LAW 196

6071 - HVAC/R Program Level One – 150 Hours

Introduction to (HVAC/R) Heating Ventilation air conditioning and Refrigeration principles. Understanding the refrigeration cycle with a focus on major components including the condenser, evaporator, and compressor and metering devices.

● Intro to HVAC/R

● Intro to Air Distribution Systems

● Basic Electricity

● Soldering and Brazing

● Alternating Current

● Fiberglass and Fabric Duct Systems

● Intro to Cooling

● Compressors

● Basic Copper & Plastic Piping Practices

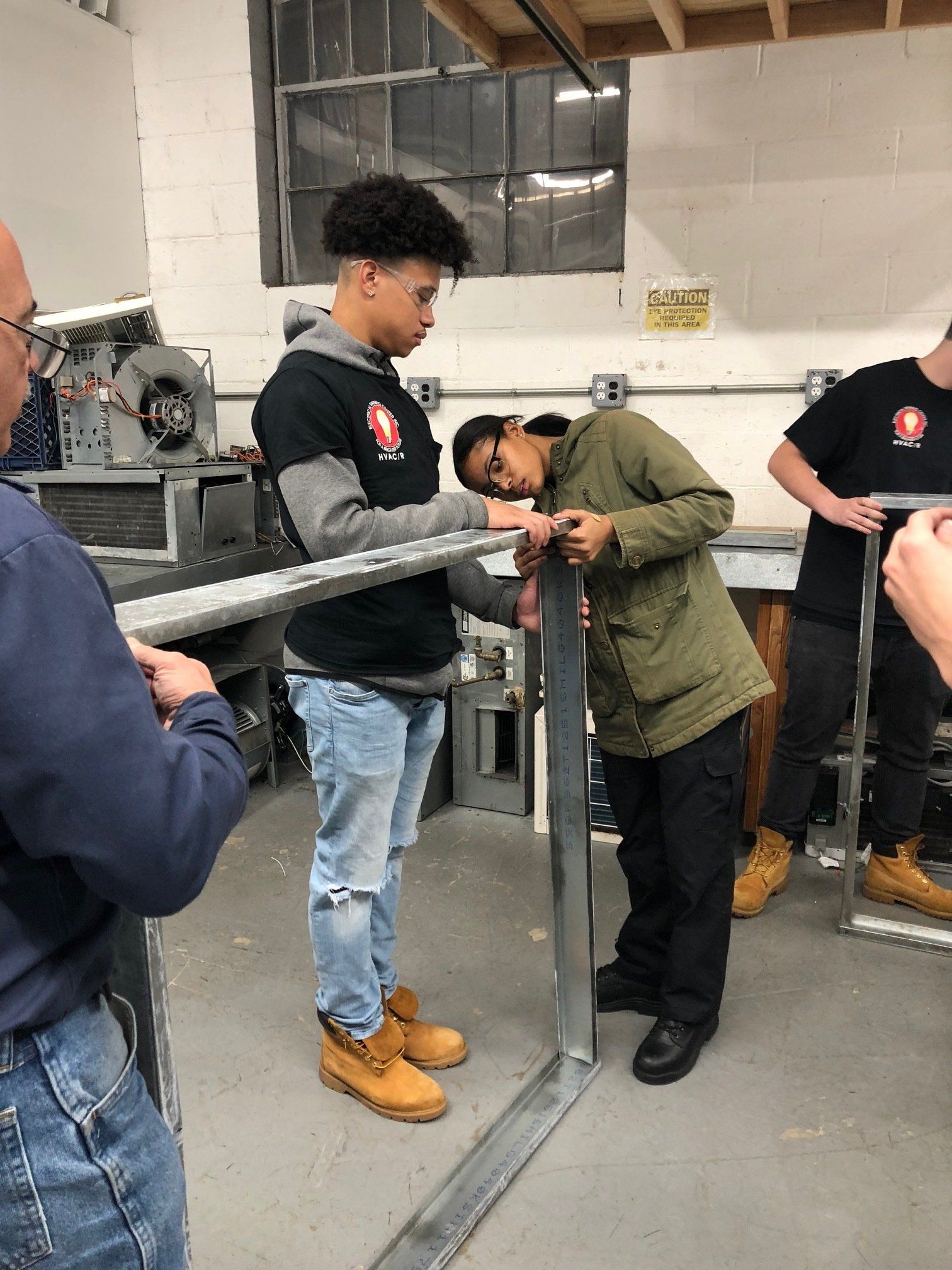

● Sheet Metal Duct Systems

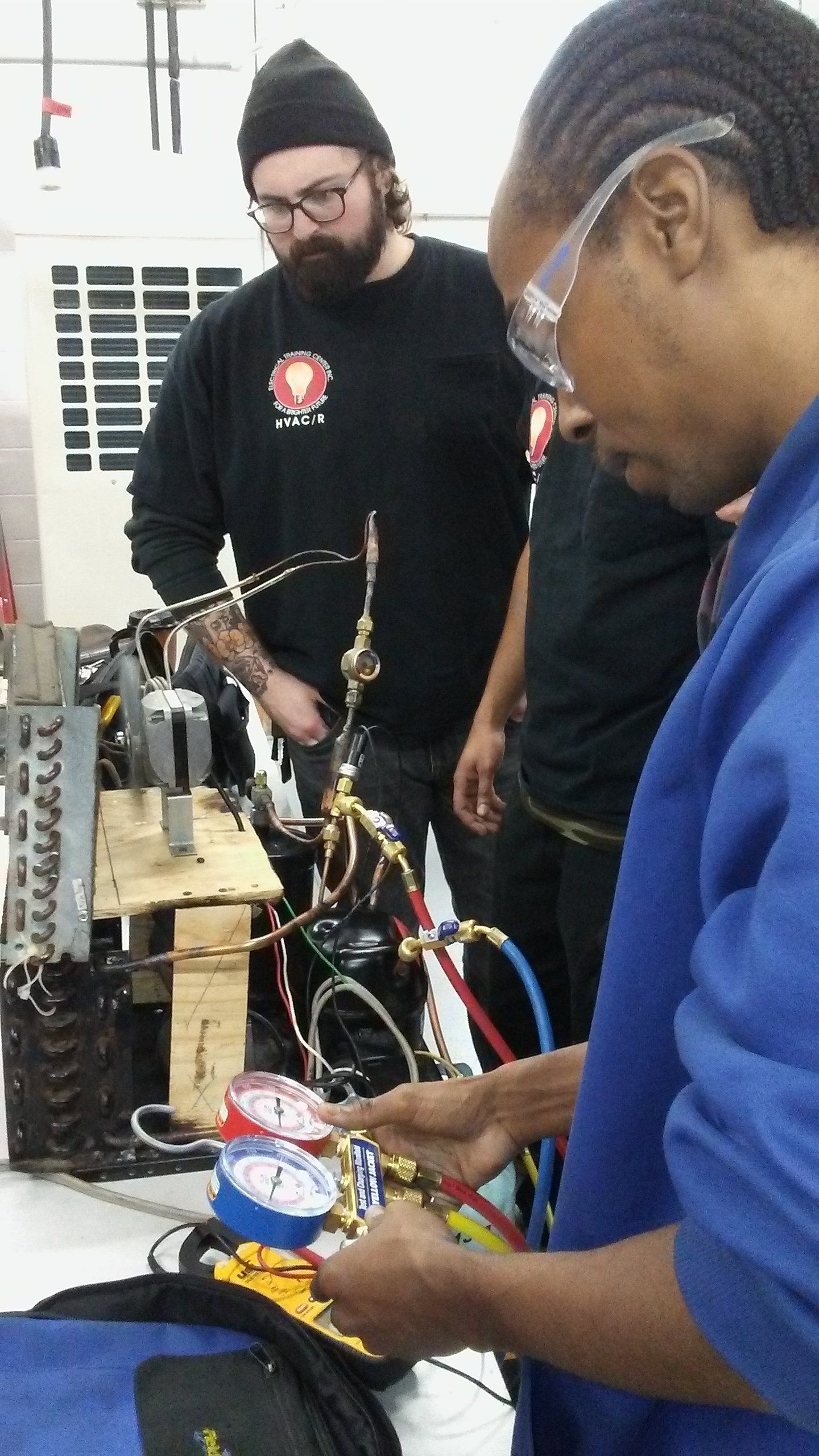

6071 – HVAC/R Program Level Two – 150 Hours

Development of installation procedures will be practiced on different air conditioning/ Refrigeration equipment. (Roof top units, Splits systems, Ductless, reach in fridges, medium temp, walk in boxes and ice machines. Reading and understanding schematics. Visual Identification of system components found within the system or on the schematics.

● Troubleshooting Cooling

● Basic Maintenance

● Refrigerants and Oils

● Commercial Airside Systems

● Metering Devices

● Air Quality Equipment

● Commercial/Industrial Refrigeration

● Leak Detection, Evacuation, Recovery and Charging

● Heat Pumps

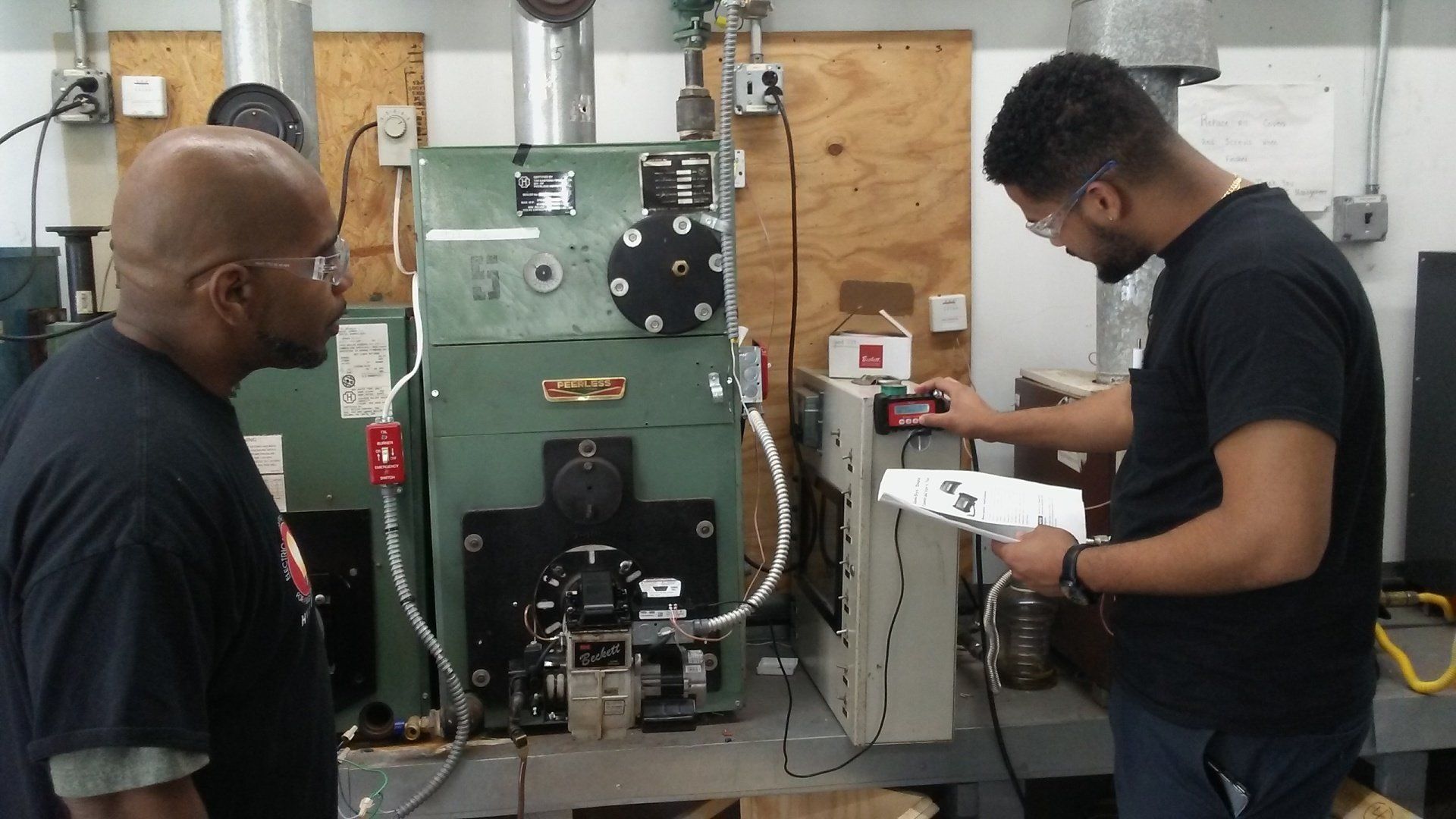

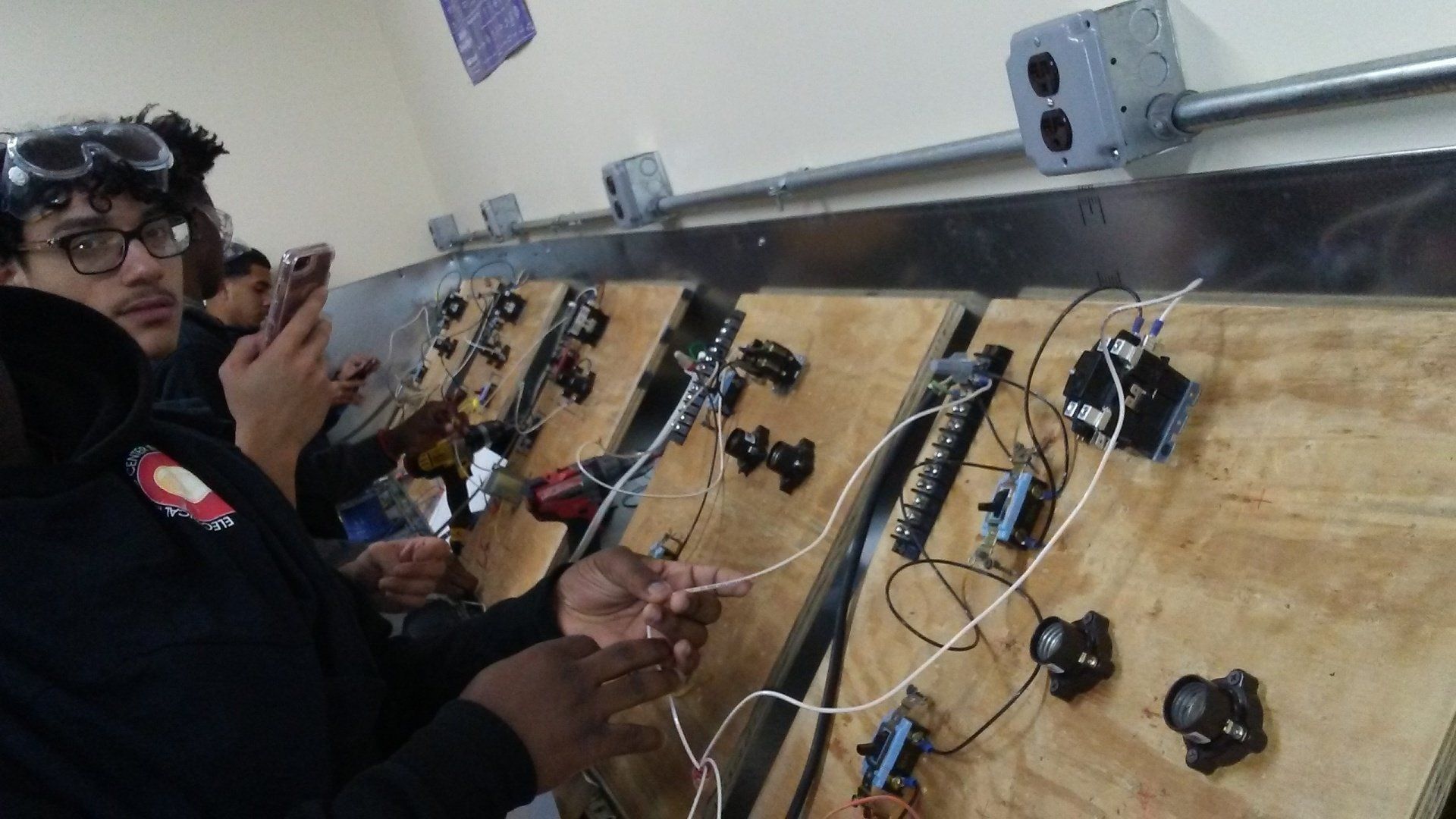

6071 – HVAC/R Program Level Three – 150 Hours

Provides students with information and skills needed to troubleshoot control circuits and electric motors found in heating and cooling equipment.

● Control Circuit and Motor Troubleshooting

● Troubleshooting Gas Heating

● Introduction to Heating

● Troubleshooting Oil Heating

● Troubleshooting Heat Pumps

● Steam Systems

● Troubleshooting Accessories

● Construction Drawing and Specifications

Virtually tour our HVAC/R labs

6071 - HVAC/R Program

Theory Hours: 308 hours

Skill Hours: 292 hours

Total Hours: 600 hours

Course length: 20 weeks – Day Sessions / 27 weeks - Eve Sessions

Day Schedule: Monday-Friday 8am to 2:30pm, Evening Monday-Friday 6pm to 10:30pm

The amount of weeks a student attends class is measured by the maximum amount of hours scheduled and does not include holidays or scheduled breaks.

- All Trades Program

All Trades 150 Hour Program

Theory Hours: 103 hours

Skill Hours: 47 hours

Total Hours: 150 hours

Course Description:

All Trades 150 Hour Program provides a basic overview of the construction trade, safety measures, career opportunities and professional development training. Safety Training includes 6032-30 Hr. OSHA Outreach Training for Construction Industry, 5023-8-Hour Fall Prevention and 5024 – 2 hr. Drug and Alcohol Awareness which fulfills the Site Safety Training Requirements for the New York City Department of Buildings Local Law 196.

6032-30hr. OSHA Outreach Training for Construction Industry:

This is a comprehensive safety course designed for anyone involved in the construction industry. Specifically devised for safety directors, foremen, and field supervisors; the program provides complete information on OSHA compliance issues. OSHA recommends Outreach Training Programs as an orientation to occupational safety and health for workers covered by OSHA 29 CFR 1926. Construction workers must receive additional training, when required by OSHA standards, on specific hazards of the job.

5023 – 8 hr. Fall Prevention:

This will cover generally familiar terms associated with falls in construction. Trainees will be able to recognize avoid and prevent falls hazards from causing harm.

Trainees should become aware of regulatory safety requirements associated with falls, including OSHA’s Subpart M. Trainees will learn how to make informed decisions when working at heights. This course is a required course that can help fulfill the requirement for an individual applying for a Site Safety Training Card. THIS IS AN AWARENESS-LEVEL TRAINING ONLY and does not provide any other qualification or authorization outside of the Site Safety Training Card.

5024 - 2-Hour Drug and Alcohol Awareness:

This will allow trainees to become generally familiar with adverse effects of drug and alcohol in the workplace. Trainees will be able to recognize problems associated with substance dependency. This seminar will explain that the purpose of this training helps trainees avoid working while under the influence of drugs and/or alcohol; also adding that this training can help trainees be less susceptible and better at recognizing, avoiding and preventing (RAP) adverse consequences of drug and/or alcohol use and abuse. This training may also help trainees better recognize and understand issues of chemical dependence that may adversely affect the lives of others who they know and love. This course is a required course that can help fulfill the requirement for an individual applying for a Site Safety Training Card. THIS IS AN AWARENESS-LEVEL TRAINING ONLY and does not provide any other qualification or authorization outside of the Site Safety Training Card.

Introduction to Construction Math:

In the construction trades, workers must use math day in and day out. Electricians and HVAC/R Technicians use math to calculate pipe length, read plans and lay out equipment. To work on all jobsites, you will use math to measure floor systems, walls and ceilings to install Electrical and HVAC/R systems. In some cases, algebra, geometry and even trigonometry may be required. This course reviews basic mathematical procedures and provides the opportunity to practice mathematical tasks related to construction activities.

Trade Mathematics:

Math is an essential skill required to advance in the Electrical and HVAC/R profession. Math is used when cutting and fitting pipe, sizing and installing ductwork, and when calculating electrical values such as current flow.

Introduction to Hand Tools:

The construction trades require a broad collection of hand tools, such as hammers, screwdrivers, and pliers, that almost every craftworker uses. Even if you already familiar with some of these tools, everyone needs to learn how to select, maintain, and use them safely. A quality tool may cost more up front, but it properly maintained, it will last for years and remain safely intact.

Introduction to Power Tools:

Power tools are used in almost every construction trade to make holes; to cut, smooth, and shape materials; and even to demolish pavement. All construction workers are certain to use power tools on the job eventually. This course provides an overview of the common types of power tools and how they work. It also describes the proper techniques required to safely operate these tools.

Introduction to Material Handling:

Lifting, stacking, transporting and unloading materials such as brick, pipe, and various supplies, are routine tasks on a job site. Whether performing these tasks manually or with the aid of specialized equipment, workers must follow basic safety guidelines to keep themselves and their coworkers safe. Our training provides guidelines for using the appropriate PPE for the material being handled and using proper procedures and techniques to carry out this job.

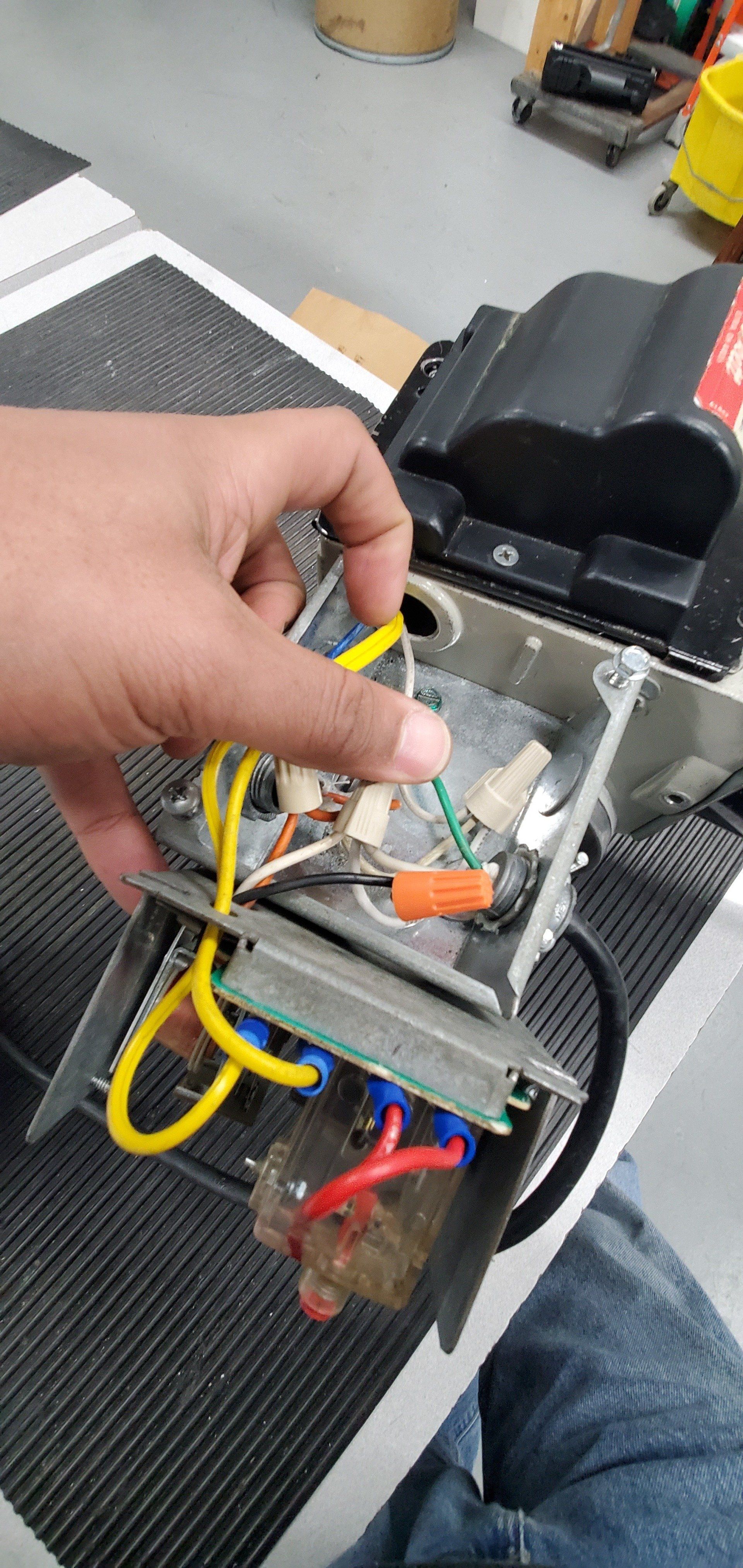

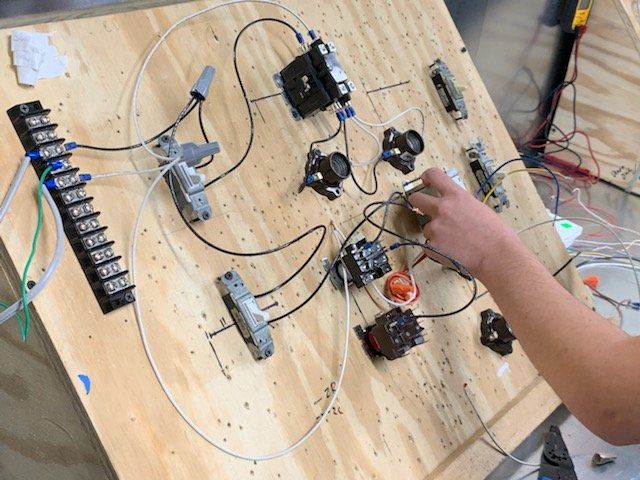

Fasteners, Hardware and Wiring Terminations:

During the installation and maintenance of Electrical and HVAC/R equipment, Electricians and HVAC/R Technicians work with a variety of fasteners, hardware, and wiring terminations. These Components must be carefully selected for the specific application and installed according to accepted practices. Using the correct components ensures that the assembled system will perform properly, and will not fail because of the wrong choice of component or its incorrect installation.

Basic Communication Skills:

The construction professional communicates constantly. The ability to communicate skillfully will help to make you a better worker and a more effective leader. Our training provides guidance in listening to understand, and speaking with clarity. It explains how to use and understand written materials, and it also provides techniques and guidelines that will help you to improve your writing skills.

Basic Employability Skills:

Becoming gainfully employed in the construction industry takes more preparation than simply filling out a job application. It is essential to understand how the construction industry and potential employers operate. Your trade skills are extremely important, but all employers are also looking for those who are eager to advance and demonstrate positive personal characteristics. Basic employability skills are needed to pursue employment successfully.

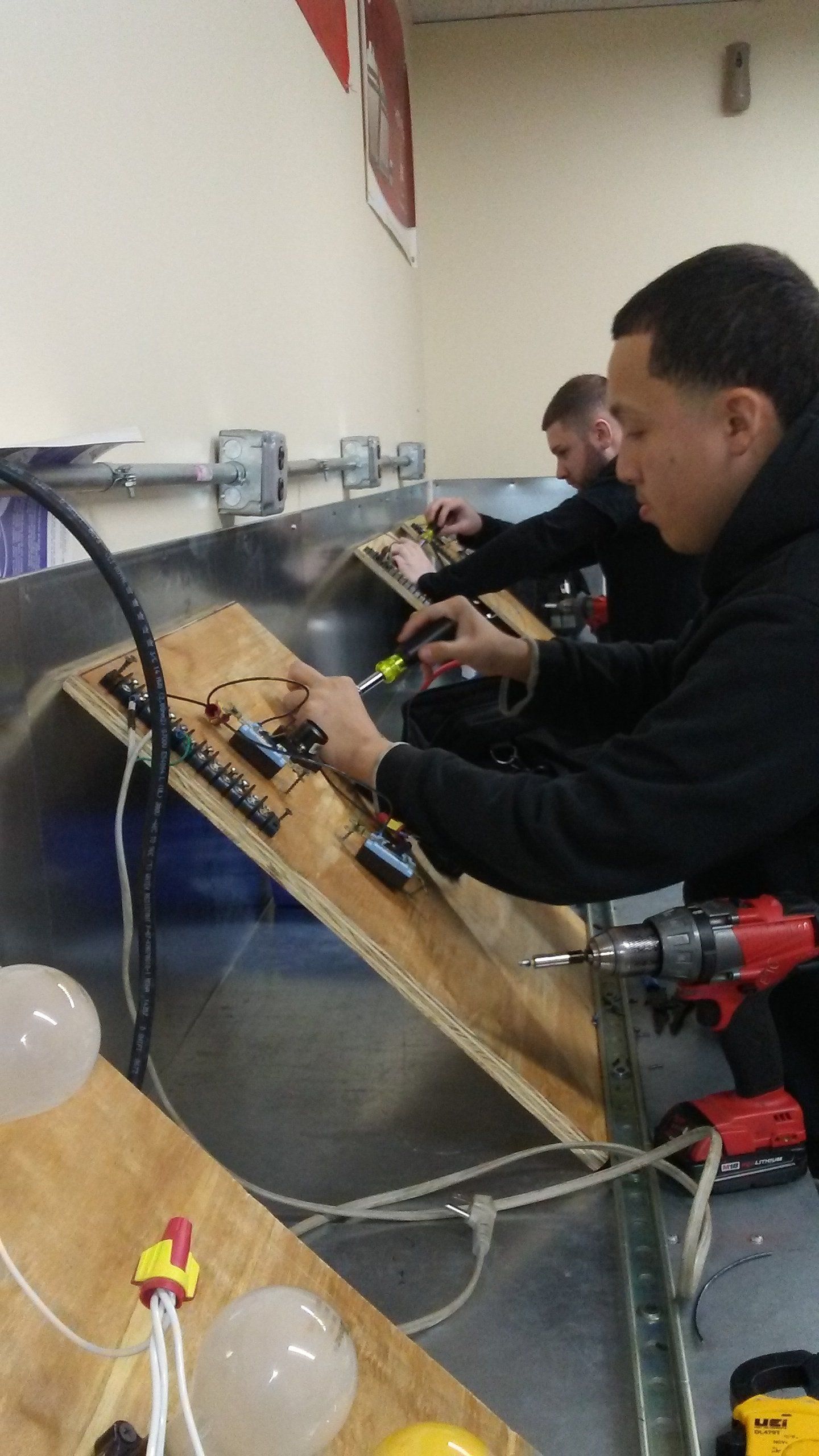

- HVAC/R Level One

HVAC/R Level One

Theory Hours: 60 hours

Skill Hours: 90 hours

Total Hours: 150 hours

Course Description:

Introduction to HVAC:

Virtually all of the millions of homes and businesses in the United States have a heating system. A large percentage of homes and business have comfort cooling systems as well. In addition, there are many thousands of stores and restaurants that use refrigeration equipment. Workers trained in the HVAC industry have the opportunity to install systems in new construction, service equipment in existing construction, and replace aging systems.

Basic Electricity:

Like most other appliances, an HVAC/R system needs electricity in order to operate. Most of the problems an HVAC/R technician encounters when faced with a service call involve the electrical system, so an understanding of electrical theory, components, and circuits is essential. Technicians must have a firm foundation to get started, allowing them to understand the circuits in complex systems and continue to grow throughout their careers.

Alternating Current:

The electrical power used to operate HVAC equipment is alternating current, or AC power. Compressor motors, fan motors, and transformers, along with the low-voltage control circuits used in managing HVAC/R systems, depend on the constantly changing nature of the AC to function. Because of this constantly changing nature, the principles you learned earlier about calculating voltage, current, resistance, and power cannot be directly applied to AC inductive circuits.

Introduction to Cooling:

To service cooling equipment, you must have a clear understanding of the refrigeration cycle. You must also understand the function of the primary refrigeration – circuit components. Technicians can apply this knowledge to all refrigeration circuits. Despite the differences in the many refrigerants and their boiling points, the basic principles presented here apply to all direct expansion refrigerant circuits.

Compressors:

The compressor is the heart of an HVAC/R system, providing the force that moves refrigerant through the cycle and raising the pressure of the refrigerant so that heat absorbed in the evaporator can be transferred to the condenser. It is essential to understand compressors and to know how to service and troubleshoot them. Although compressors are durable, factors such as the state of the refrigerant circuit and the quality of the power supply can contribute to their failure. HVAC/R technicians must understand how these and other factors influence compressor operation.

Air Distribution Systems:

Most heating and cooling systems use ductwork to deliver conditioned air to the spaces being cooled or heated. The ductwork may be made of sheet metal, fiberglass duct board, fabric, or flexible duct. The performance of the HVAC system is closed linked to the quality of the air distribution system. The ductwork must be of the proper size and type, and must be correctly installed and sealed.

Basic Copper and Plastic Piping Practices:

Copper tubing and piping is used extensively in HVAC work. Copper is the base material for virtually all common refrigerant piping. Plastic piping is used in heating and cooling systems for a variety of purposes. Plastic piping may be used to carry chilled water for large cooling systems, condenser water for water cooled mechanical systems or even to vent high efficiency furnaces.

Soldering and Brazing:

Soldering is used primarily to join copper water lines and condensate lines in the HVAC/R craft. When mechanically strong, pressure resistant joints are needed for refrigerant lines, the process used is brazing. Both soldering and brazing demand careful attention to safety due to the hazards associated with flammable gases and open flames. With some practice, HVAC/R technicians can soon master soldering and brazing techniques.

Sheet Metal Duct Systems:

HVAC ductwork can be made of sheet metal or fiberglass duct board. Because the interior surfaces of sheet metal ducts are smooth, these ducts offer less resistance to airflow than fiberglass duct board. However, in most cases they must be insulated to reduce noise transmissions, minimize the heat transfer, and prevent condensation. Therefore, working with sheet metal ductwork requires knowledge of various types of metals and insulation practices, as well as unique methods for joining and supporting sheet metal ductwork. Sheet metal ductwork systems also include additional components for efficient air distribution, such as dampers and takeoffs.

Fiberglass and Fabric Duct Systems:

Fiberglass duct board has been used successfully in both residential and commercial installations for many years. It is lightweight and easy to handle. The duct provides its own insulation, so it is not necessary to add insulation as it is with sheet metal duct.

Fabric duct systems continue to gain popularity in commercial, industrial and institutional applications. They are affordable, require very limited labor to install, and can be applied in a number of situations. Maintenance and cleaning of these systems is also very simple.

- HVAC/R Level Two

HVAC/R Level Two

Theory Hours: 70 hours

Skill Hours: 80 hours

Total Hours: 150 hours

Course Description:

Troubleshooting Cooling:

The refrigeration circuit is a closed loop system, so it is not always easy to determine the location of a problem in the system. Since the operation of the refrigerant circuit can be affected by external conditions, it can also be challenging to determine if a problem is within the system or the result of an external influence. A thorough understanding of the refrigeration circuit provides the basis for matching specific symptoms to probable causes. An experienced service technician is able to recognize refrigeration cycle failure patterns quickly and efficiently and knows how to apply effective solutions.

Refrigerants and Oils:

HVAC/R technicians must be thoroughly familiar with the refrigerants and oils used in today’s systems. Laws originally adopted years ago mandate the elimination of many refrigerants and their replacement with new products that are more environmentally friendly. Many new refrigerants are not compatible with traditional lubricants, prompting the development of new oils as well. Our training presents many of the refrigerants and oils in common use and introduces some with future potential.

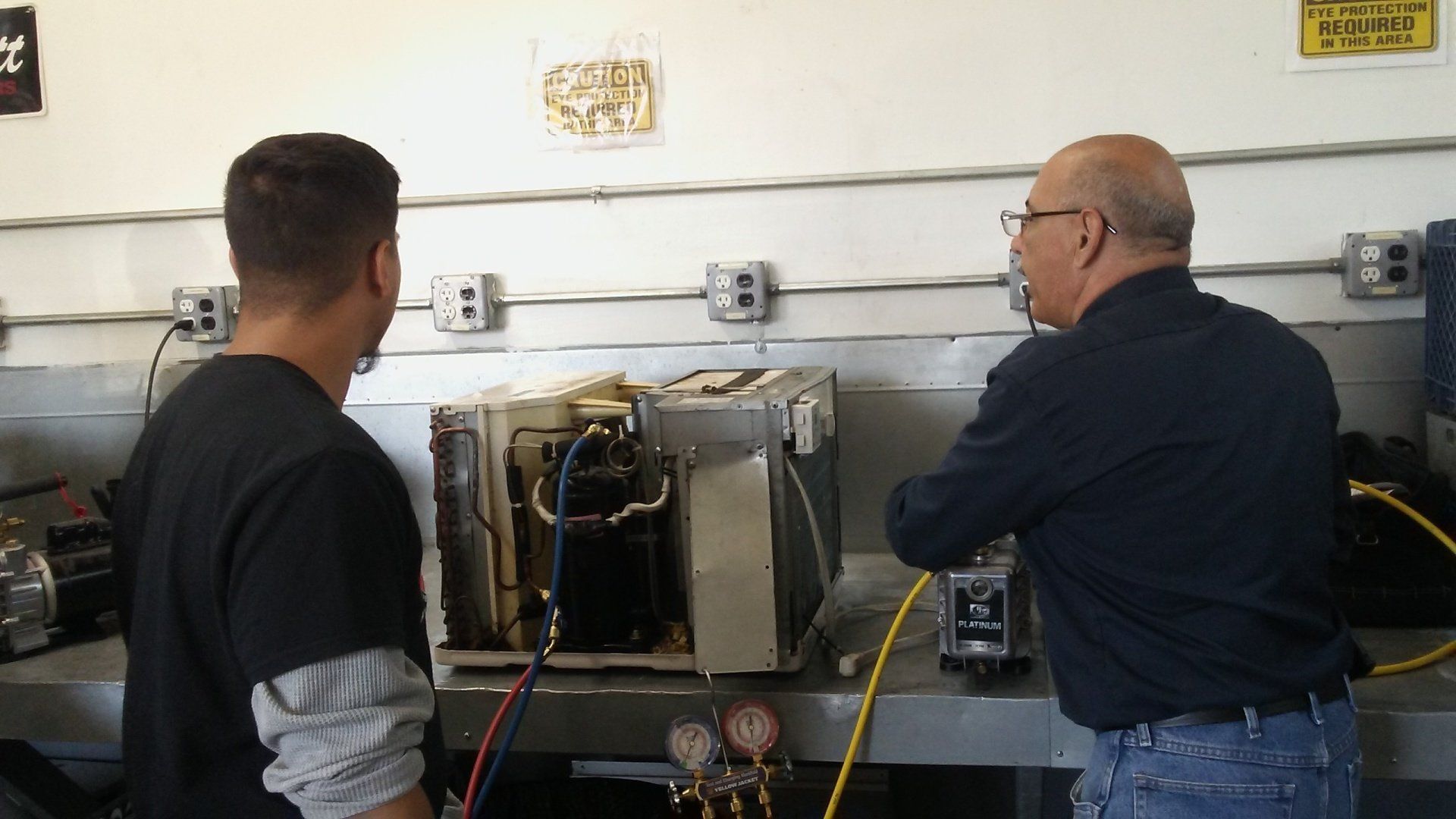

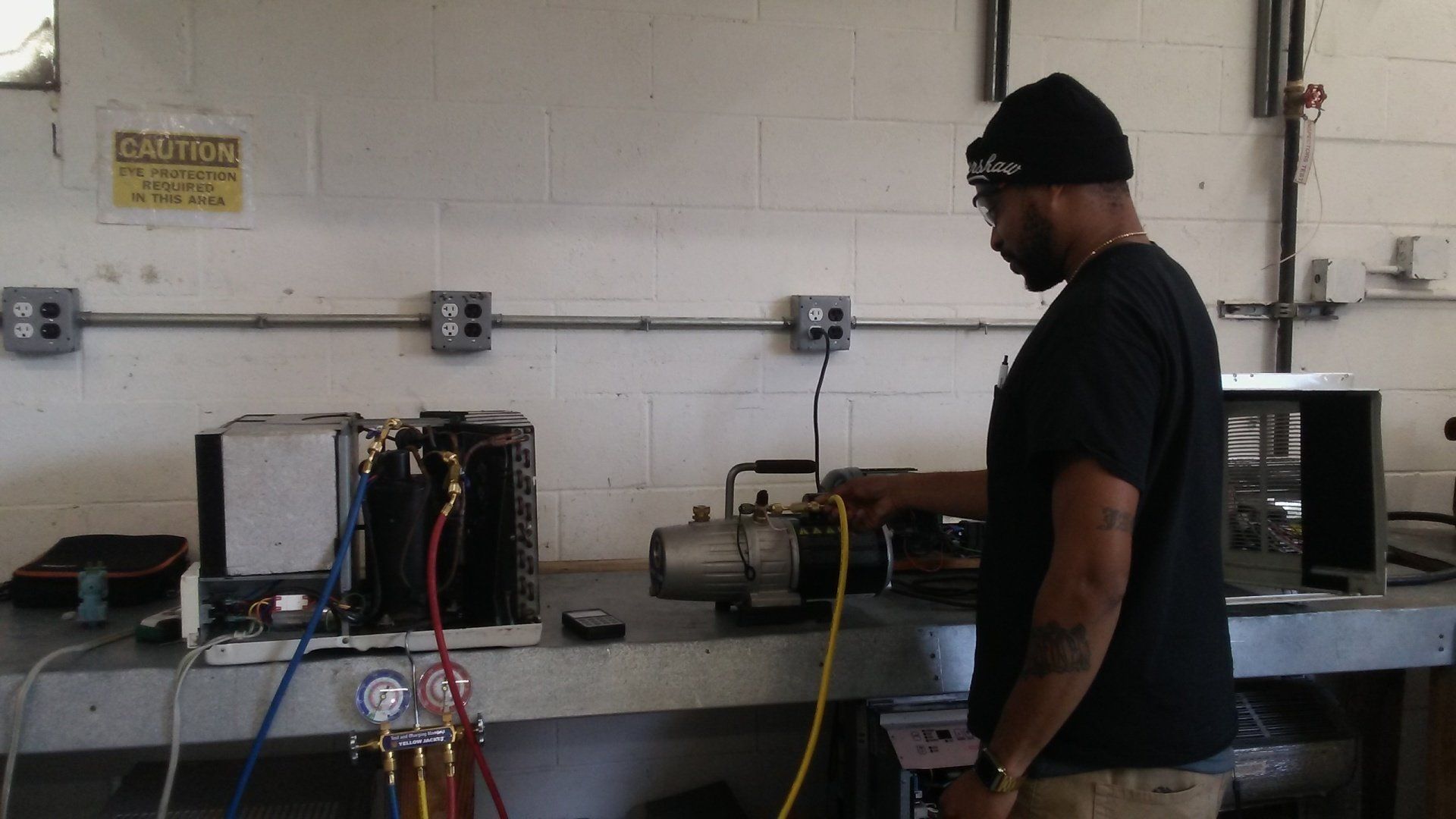

Leak Detection, Evacuation, Recovery and Charging:

Proper handling of refrigerants in accordance with EPA guidelines is one of the most important tasks for HVAC/R technicians, who must perform critical tasks like leak detection, evacuation, recovery and charging of the refrigeration circuit. Work related to the refrigerant circuit is expensive and time-consuming, and it must be done with attention to detail to ensure system users enjoy efficient, reliable operation in the end.

Metering Devices:

The metering device provides the pressure drop that a refrigerant needs in order to boil in the evaporator and absorb heat from the conditioned space. There are a number of different styles, but all provide a similar function. HVAC/R technicians must be able to identify various metering devices and understand their operation. The different types require different service procedures and affect the approach to charging refrigerant into different systems.

Basic Maintenance:

Equipment maintenance requires HVAC/R technicians to make intelligent decisions regarding the correct materials to use in specific situations. They must be familiar with common maintenance items such as air filters and lubricants. Our training presents information related to maintenance-oriented materials and their applications and presents guidelines for system inspections and periodic maintenance procedures.

Commercial/Industrial Refrigeration:

Our training focuses on commercial and industrial applications of refrigeration. It covers the equipment, control systems, and refrigerants used for these purposes. It compares and contrasts these methods and components used in commercial and industrial applications with those used in comfort cooling systems.

Commercial Airside Systems:

You may have seen office buildings and shopping malls with many air conditioning units on the roof. These are likely to be packaged units in which the ductwork penetrates the building. Large buildings have different needs than small buildings. For example, some zones in the building may be calling for heat, while others are calling for cooling, and others are making no demands. The system design must accommodate these differences. In commercial systems, it is common to find single systems serving multiple zones, with each zone having its own comfort control device. These applications require special air distribution equipment not commonly found in residential applications.

Air Quality Equipment:

There are many accessories that can be added to an HVAC/R system to improve the comfort level and the quality of the air in a building. Other accessories can improve the operating efficiency of the system, resulting in lower cost to the user. The quality of the air in homes and elsewhere is affected by dust, molds, and other contaminants. Other accessories, such as humidifiers, are designed to overcome problems that reduce the indoor comfort level. Because these accessories have become very commonplace, it is essential that HVAC/R specialists know how to properly install and service them.

- HVAC/R Level Three

HVAC/R Level Three

Theory Hours: 75 hours

Skill Hours: 75 hours

Total Hours: 150 hours

Course Description:

Control Circuit and Motor Troubleshooting:

Most malfunctions that occur in HVAC/R equipment are caused by failure in the power distribution of control circuits. Technicians must understand how the various components function and be able to interpret the schematics, wiring diagrams, and other service literature. In addition, new technologies such as variable motor drives and electronically commutated motors re adding more complexity. The successful troubleshooter can read schematics and wiring diagrams to understand the underlying operating sequences and apply that understanding to troubleshooting.

Heat Pumps:

Heat pumps provide both cooling and heating using the mechanical refrigeration cycle. The secret to this capability is that even cold air contains some heat. The heat pump can extract that heat by reversing the refrigeration cycle. A heat pump contains a few more control devices than a cooling-only system, and its heat exchangers are larger because they serve two functions. Other than that, a heat pump looks just like a common air conditioning system.

Troubleshooting Heat Pumps:

Our training reviews the operation of heat pumps and presents methods and procedures for troubleshooting them. Heat pumps contain more control devices and have more complex circuits than a cooling-only system. Depending on the malfunction, the cooling and heating functions are usually examined separately, although some problems affect both modes of operation. Because heat pumps are unique, some of the applicable troubleshooting tasks are unique as well.

Troubleshooting Accessories:

Residential furnaces, especially in cold, dry northern climates, are often equipped with humidifiers to maintain a healthy moisture level in the indoor air. Electronic air cleaners may also be installed in both residential and commercial environments. Economizers are common in commercial systems. Energy and heat recovery ventilators are also another accessory that can be applied in both residential and commercial systems. Servicing these types of devices requires some specialized knowledge. This is especially true of economizers, because there are several types, each with its own specific operating characteristics.

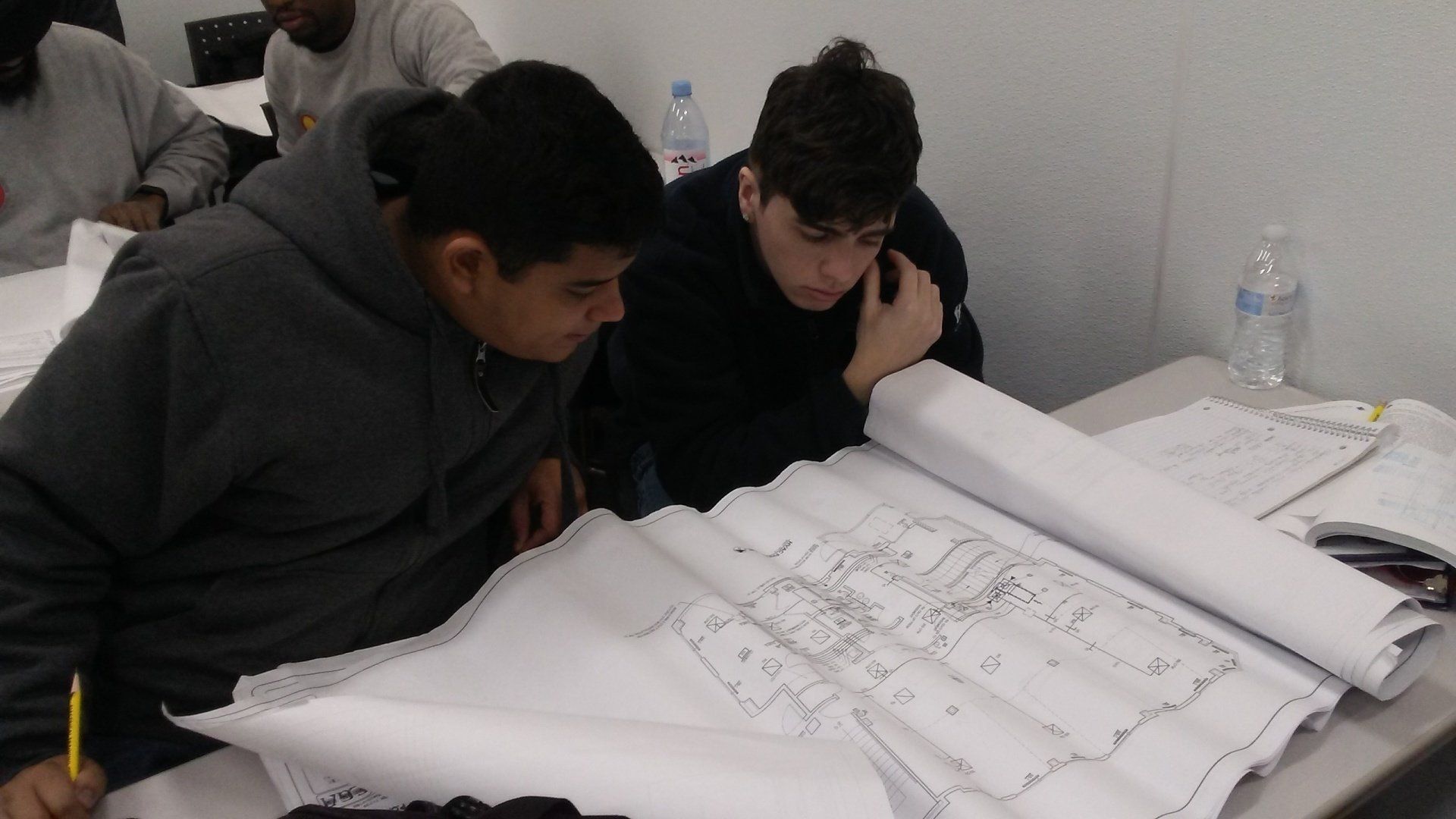

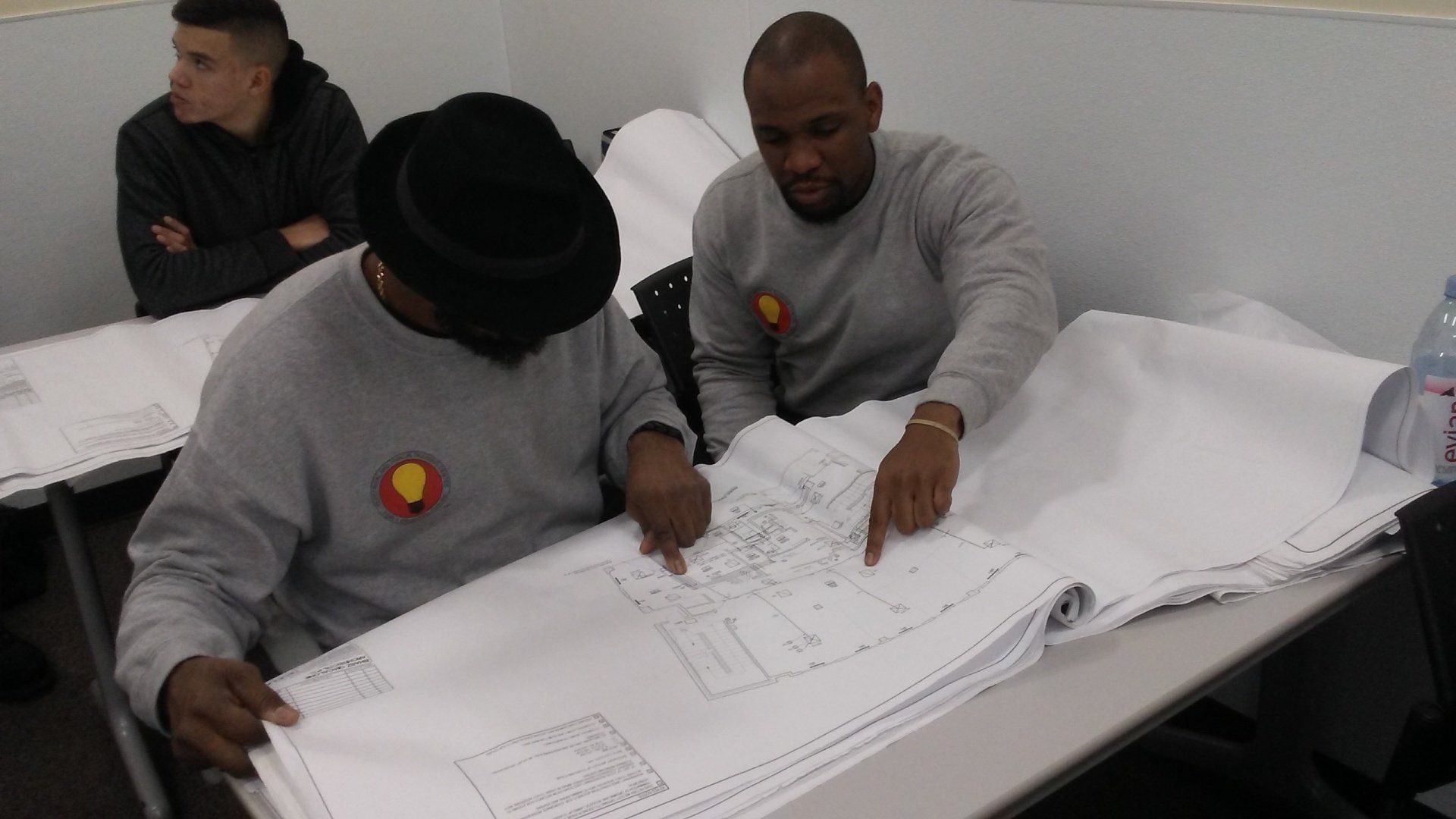

Construction Drawings and Specifications:

Anyone involved in the installation of the heating and cooling equipment for new construction must be able to interpret the project drawings and specifications. The drawings show the locations of equipment, duct runs, piping runs, and electrical wiring. During the estimating and planning processes, the drawings are used to determine the amount and types of equipment, accessories, and materials needed for the job. Correct interpretation of the drawings is essential in order to determine the correct price for the job, and to have the correct amounts and types of equipment and materials available. A technician or installer who does not learn to interpret them properly is unlikely to advance very far in his or her career.

Troubleshooting Gas Heating:

Gas Furnaces and other gas heating devices utilize a variety of controls. Most of these controls are safety devices that either shut the system down in the event of a problem or prevent it from operating if certain conditions are not met in a specified sequence. Service technicians must understand how these devices interact to control the system. They must also learn to recognize combustion related problems and be able to properly test the combustion system using specialized test instruments.

Slide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButton

Slide title

HVAC/R Program

Button

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButtonSlide title

Write your caption hereButton

Slide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButton

Slide title

Write your caption hereButtonSlide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButtonSlide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButtonSlide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButtonSlide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButton

Slide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButton

6071 - HVAC/R Program Request Form

More Information

We will get back to you as soon as possible

Please try again later

Become an

Electrical

or

HVAC/R

Instructor

For More Information

Call: (631) 226-8021

Ask for

Robert McLaughlin

Copiague, NY 11726

SIGN UP FOR OUR NEWSLETTER

We will get back to you as soon as possible

Please try again later